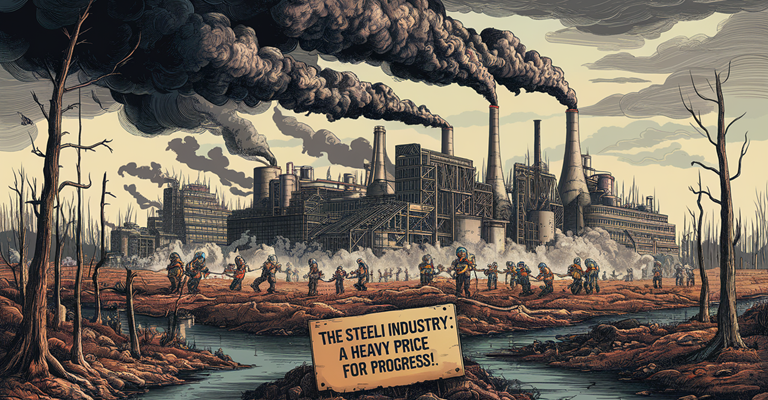

The steel industry stands as one of the pillars of modern civilization, providing the backbone for infrastructure, transportation, and countless consumer goods. However, this industrial behemoth also casts a long shadow over the environment, leaving a significant carbon footprint and ecological degradation in its wake.

As the world grapples with the urgency of climate change and environmental sustainability, understanding the impact of the steel industry is paramount. Equally important is the exploration of feasible solutions to mitigate its adverse effects.

Here is an overview of how the steel industry impacts the environment and some solutions to ease the effects of this.

The Environmental Toll of Steel Production

Steel production is a resource-intensive process that exacts a heavy toll on the environment. One of the primary concerns is carbon dioxide (CO2) emissions. The production of steel is responsible for a significant portion of global CO2 emissions, with estimates suggesting it contributes around 7% of the world’s total. The primary source of these emissions is the use of carbon-intensive fuels, such as coal, in the blast furnace process to extract iron from its ore.

Beyond greenhouse gas emissions, steel production also generates other pollutants. These include particulate matter, sulphur dioxide, nitrogen oxides, and heavy metals, which contribute to air and water pollution. Furthermore, the extraction of raw materials, such as iron ore and coal, disrupts ecosystems, damages habitats, and contributes to deforestation and biodiversity loss.

Addressing the Challenges

The environmental challenges posed by the steel industry are formidable, but there are promising avenues for mitigation and improvement:

Adoption of Cleaner Technologies

Transitioning to cleaner production technologies is crucial. One such innovation is the development of electric arc furnaces (EAFs), which use electricity instead of carbon-intensive fuels to melt scrap steel and produce new steel. EAFs have a significantly lower carbon footprint compared to traditional blast furnaces and offer the potential for renewable energy integration.

Increased Efficiency and Recycling

Improving the efficiency of steel production processes can reduce resource consumption and emissions. Additionally, promoting recycling and the use of scrap steel as a raw material can further diminish the industry’s environmental impact. Recycling steel not only helps preserve resources but also diminishes energy consumption and emissions linked to primary steel production.

Carbon Capture and Storage (CCS)

Implementing CCS technologies can capture CO2 emissions from steel plants and prevent them from entering the atmosphere. Captured CO2 can then be transported and stored underground or utilized in other industrial processes, thereby reducing overall emissions. Carbon Clean technologies, for example, can significantly reduce emissions from steel production, fostering a more sustainable industry.

Top of Form

Renewable Energy Integration

Shifting towards renewable energy sources – such as wind and solar – to power steel plants can significantly decrease carbon emissions associated with steel production. Moreover, integrating renewable energy with steelmaking processes, such as using hydrogen produced from renewable sources as a reducing agent in steel production, holds promise for further reducing emissions.

Regulatory Measures and Corporate Responsibility

Governments play a crucial role in setting regulations and standards to curb emissions from the steel industry. Implementing carbon pricing mechanisms, emissions trading schemes, and stringent environmental regulations can incentivize companies to invest in cleaner technologies and practices.

Additionally, fostering corporate responsibility and encouraging transparency in reporting environmental performance can drive industry-wide improvements.

Conclusion

The steel industry’s environmental impact is undeniable, but it is not insurmountable. By embracing technological innovation, improving efficiency, and adopting sustainable practices, the industry can reduce its carbon footprint and ecological footprint while continuing to meet global demand for steel.

However, achieving meaningful progress will require collaboration among governments, industry stakeholders, and civil society to implement effective policies and drive systemic change.

With dedicated efforts and a commitment to sustainability, the steel industry can evolve into a more environmentally responsible and resilient sector, contributing to a greener and more sustainable future.

Comments